Introduction

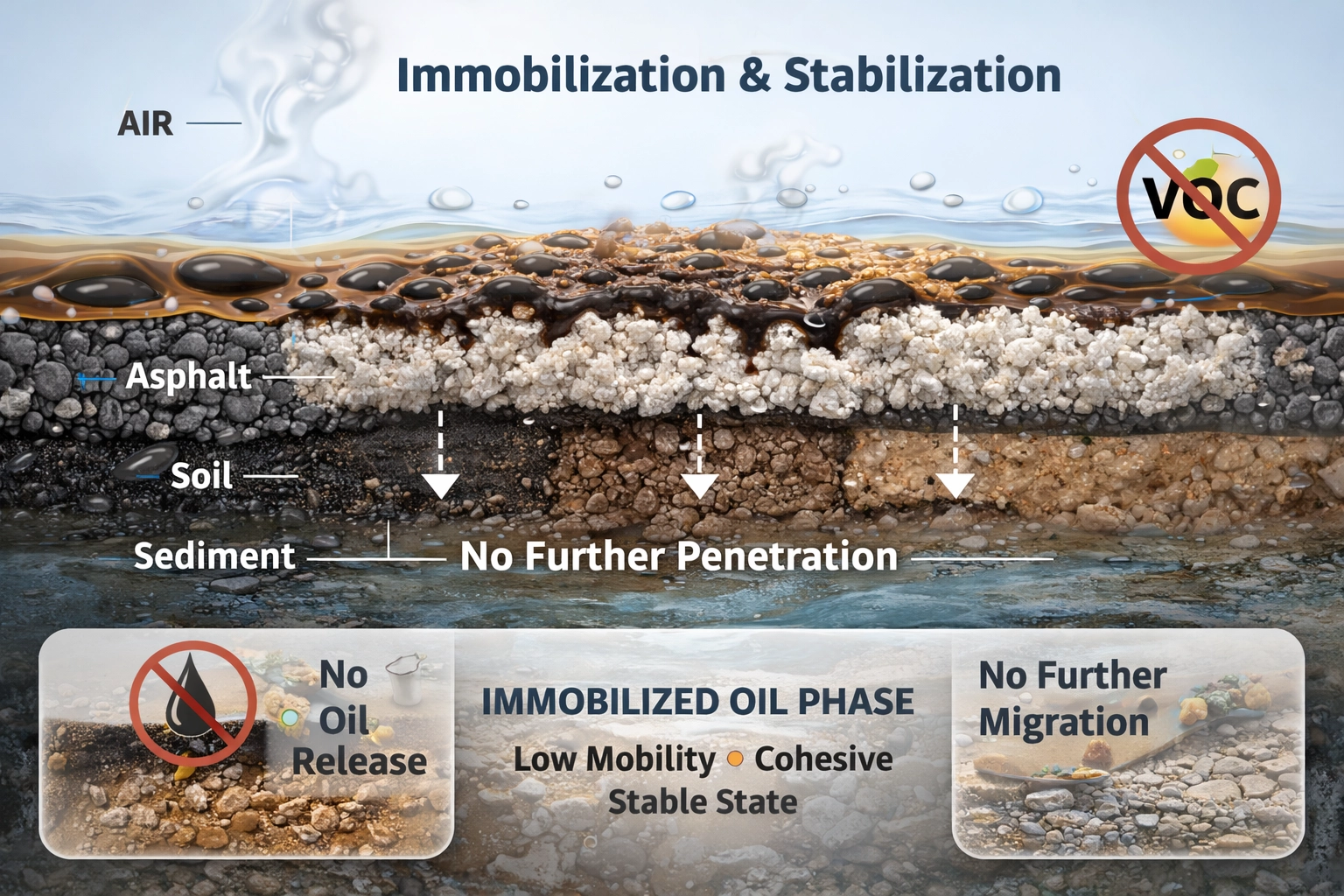

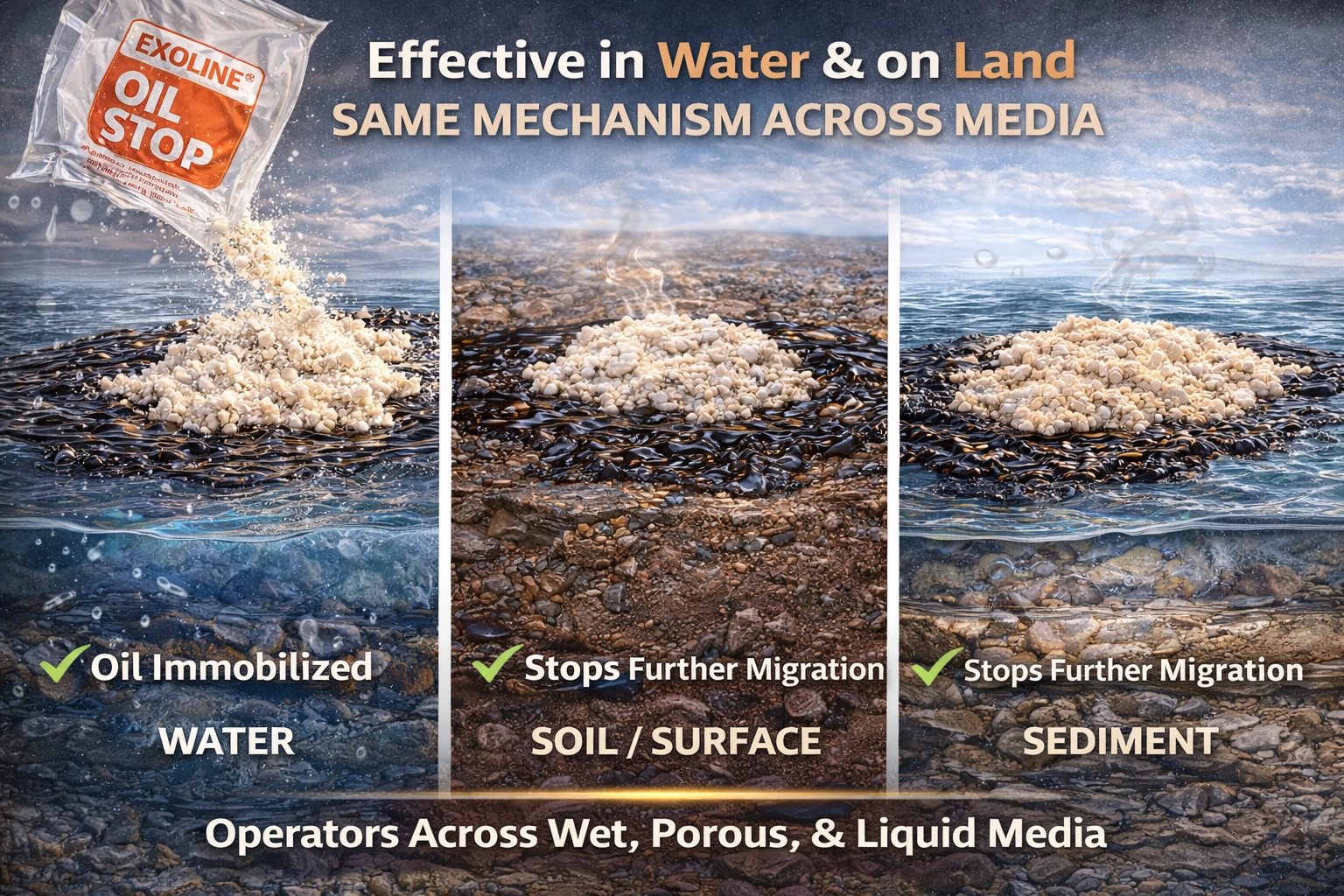

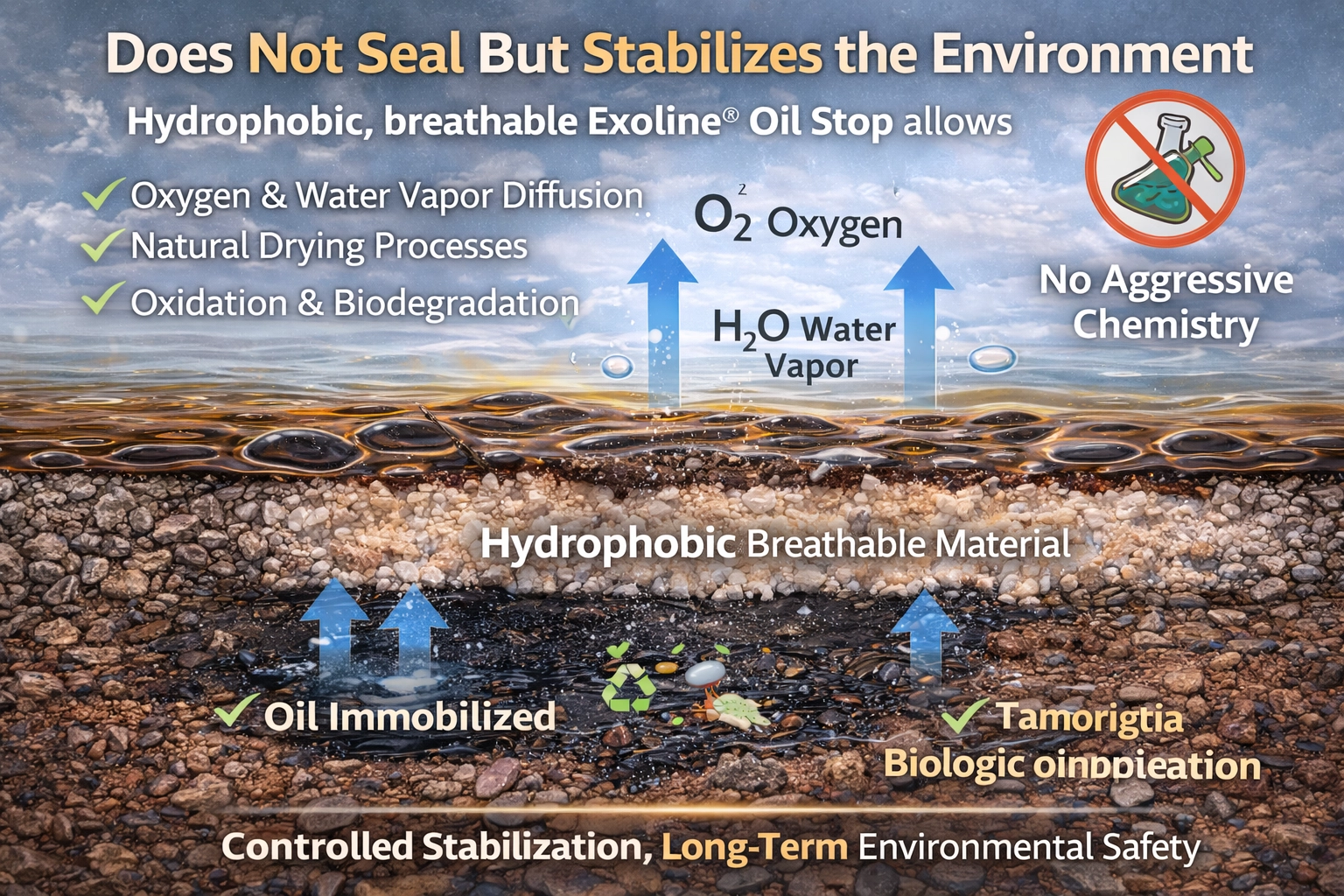

Exoline® Oil Stop immobilizes contamination into a non-flowing, stable state within 1 - 2 minutes, thereby preventing re-release, infiltration, and the evaporation of volatile fractions. Its hydrophobic structure selectively binds oil, while allowing the natural flow of gases and water vapor in the surrounding environment.

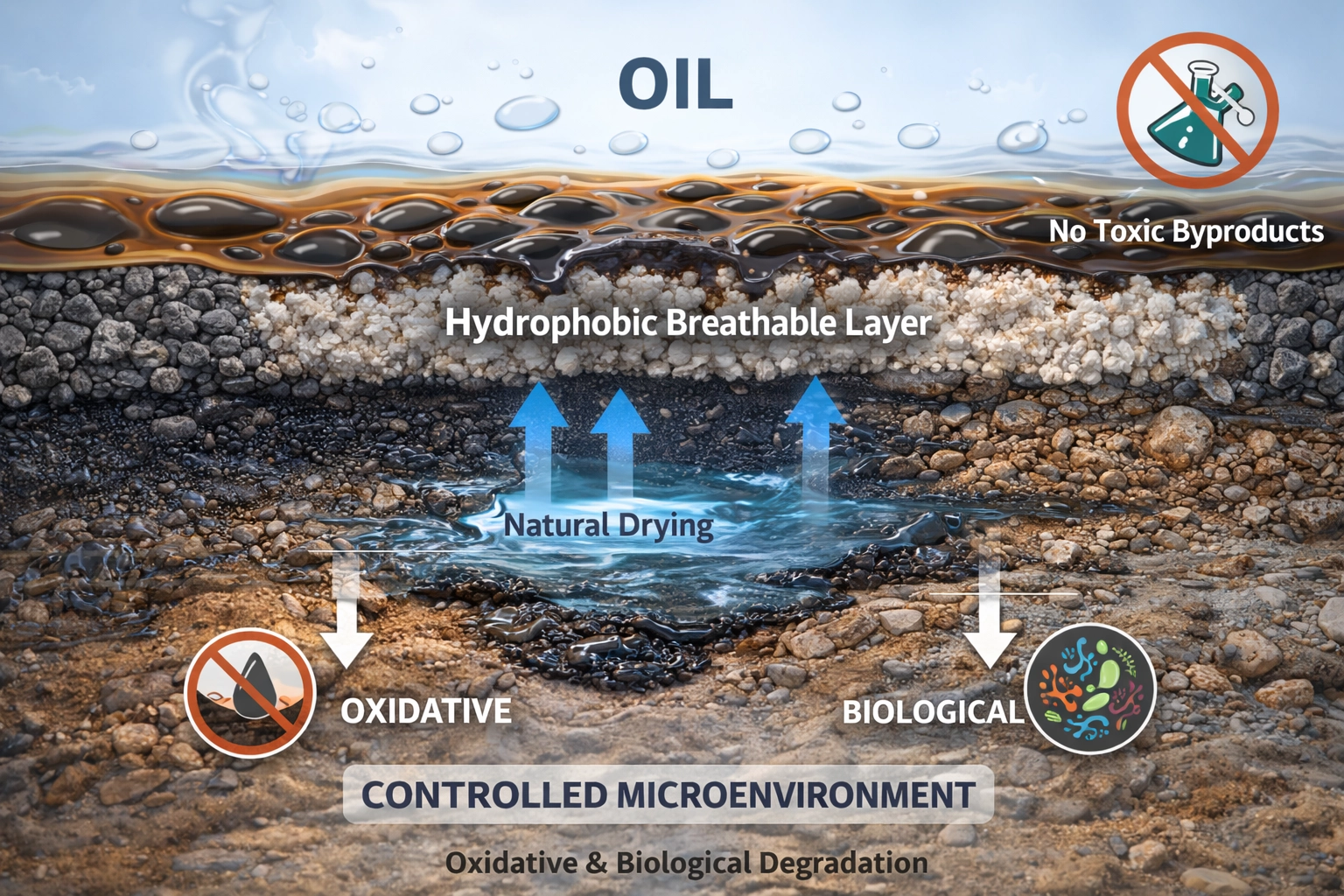

The technology does not rely on aggressive chemical degradation. Instead, Oil Stop creates a stable microenvironment that supports natural oxidative and biological degradation processes, without generating toxic by-products.

Exoline® Oil Stop is fully effective as a standalone solution, while also functioning as a system: it significantly enhances the performance of commonly used absorbent materials particularly perlite, zeolite, vermiculite, and polypropylene (PP)-based absorbents.

As a result of this performance enhancement, water uptake is reduced, oil-binding stability is increased, the risk of re-release is minimized, and the overall volume of generated waste is significantly reduced.

Oil-saturated Exoline® Oil Stop can be briquetted and is suitable for energy recovery. Stable binding ensures that the material does not release oil during transportation or storage, allowing it to be processed safely. Due to the high energy content of the briquetted form, it can be utilized as an alternative fuel in industrial incineration facilities or cement plants, significantly reducing waste management costs.

This approach delivers not only environmental benefits, but also actively supports the circular economy by enabling oil-contaminated waste to be securely managed and partially transformed into a recoverable energy resource, while minimizing secondary environmental impact.

The system’s key advantages are rapid control, stable binding, and environmental safety, enabling subsequent treatment or removal steps to be carried out under controlled and secure conditions.

-4.webp)